Metal fabrication and repair work require efficient welding techniques to ensure strong and reliable joints. One of the most convenient methods is Gasless MIG Wire welding, which eliminates the need for external shielding gas. This method is gaining popularity due to its simplicity, portability, and effectiveness in outdoor conditions. However, safety is a crucial aspect of welding, and using a welding blanket is essential to protect the work environment and ensure worker safety.

Understanding Gasless MIG Wire Welding

Gasless MIG welding, also known as Flux-Cored Arc Welding (FCAW), uses a hollow wire filled with flux to create a shielding effect during welding. Unlike traditional MIG welding, which requires an external gas supply to protect the weld pool from atmospheric contamination, Gasless MIG Wire produces its own shielding effect by releasing gases from the flux core. This makes it an excellent choice for outdoor welding, where wind and environmental factors can interfere with gas-shielded welding processes.

Advantages of Gasless MIG Wire Welding

Portability: Since no gas tanks are required, this method is easy to transport and set up in remote or outdoor locations.

Wind Resistance: The flux inside the wire provides protection, making it ideal for outdoor welding where wind can disrupt a gas shield.

Penetration and Strength: Gasless MIG welding produces strong welds with deep penetration, making it suitable for structural work.

Ease of Use: Beginners can quickly learn and execute Gasless MIG welding since it doesn't require complex gas flow adjustments.

Cost-Effective: Eliminating the need for gas cylinders reduces expenses related to gas procurement, storage, and handling.

Importance of Using a Welding Blanket

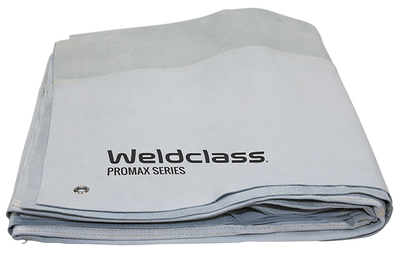

Welding generates extreme heat, sparks, and molten metal splatter, which can pose hazards to both the welder and the surrounding work area. A welding blanket is a crucial safety tool designed to shield surfaces, equipment, and personnel from welding-related hazards.

Key Benefits of a Welding Blanket

Fire Prevention: Welding blankets are made from flame-resistant materials such as fiberglass or silica, which prevent fires caused by sparks or molten metal.

Protecting Surroundings: Whether welding indoors or outdoors, a welding blanket helps safeguard floors, machinery, and nearby materials from damage.

Improving Safety: By containing welding splatter, these blankets reduce the risk of burns and injuries to workers in the vicinity.

Versatile Applications: Apart from welding, these blankets can be used in cutting, grinding, and other metalworking tasks.

Choosing the Right Gasless MIG Wire

Selecting the appropriate Gasless MIG Wire is essential to achieve the best welding results. Here are some key factors to consider:

1. Wire Diameter

The most common diameters for Gasless MIG wire are 0.030" and 0.035".

Thicker wires (0.035") provide deeper penetration, making them suitable for thicker metal pieces.

Thinner wires (0.030") work well for sheet metal and lighter materials.

2. Material Compatibility

Mild Steel: Use E71T-GS or E71T-11 flux-cored wires for welding mild steel.

Stainless Steel: Choose stainless steel flux-cored wire for corrosion-resistant applications.

Aluminum: Gasless aluminum MIG wire is available but requires specialized equipment.

3. Polarity Setting

Gasless MIG welding requires a DCEN (Direct Current Electrode Negative) setting on the welder. This ensures proper penetration and minimizes spatter.

How to Use a Welding Blanket Effectively

To maximize the effectiveness of a welding blanket, follow these tips:

1. Proper Placement

Cover nearby surfaces, floors, or any flammable materials within the welding zone.

Drape the blanket over exposed machinery to prevent damage from sparks.

2. Securing the Blanket

Use welding clips or heavy objects to keep the blanket in place.

Ensure the blanket fully covers the target area to prevent accidental fires or burns.

3. Regular Maintenance

Check for burns, holes, or damage in the welding blanket before each use.

Replace worn-out blankets to maintain safety and effectiveness.

Common Mistakes to Avoid in Gasless MIG Welding

Even though Gasless MIG Wire welding is user-friendly, some common mistakes can compromise the quality of the welds. Here are key pitfalls to avoid:

Incorrect Wire Tension: Too much or too little tension can cause feeding issues, leading to inconsistent welds.

Improper Polarity: Always set the welder to DCEN for optimal performance.

Fast Travel Speed: Moving the torch too quickly can result in weak welds with poor penetration.

Neglecting Safety Measures: Always wear protective gear and use a welding blanket to prevent injuries and fire hazards.

Conclusion

Gasless MIG Wire welding is an excellent method for those looking for an efficient and portable welding solution. Its ability to work without external shielding gas makes it ideal for outdoor applications, and its strong welds ensure durability. However, safety should always be a priority. Using a high-quality welding blanket significantly reduces the risks associated with welding, protecting both workers and their surroundings.

By understanding the best practices, choosing the right materials, and prioritizing safety, welders can achieve high-quality results while maintaining a safe working environment. Whether you are a professional fabricator or a DIY enthusiast, mastering Gasless MIG welding with proper safety measures will help you complete projects efficiently and securely.